Gelbo Test Blog

Understanding the Gelbo Flex Test: Enhancing Packaging Durability Through Advanced Testing.

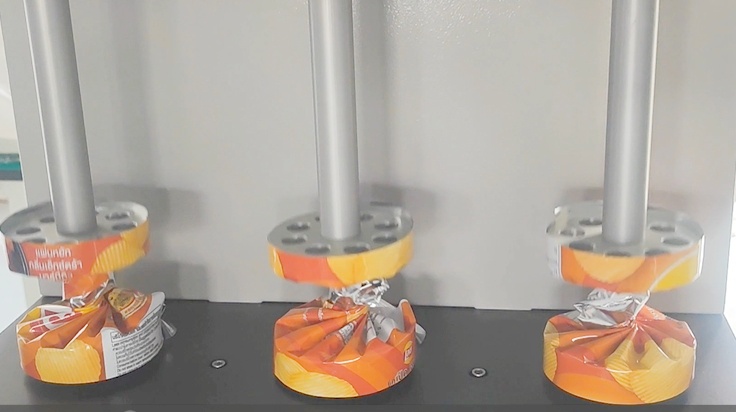

The Gelbo Flex Test is a critical evaluation tool designed to simulate the mechanical stresses that barrier films endure during transportation, handling, and storage. By subjecting films to repeated flexing, twisting, and compression, this test measures their ability to resist failure, ensuring that packaging materials maintain their protective properties throughout the product lifecycle. In industries like food packaging, medical devices, and electronics, this test is essential for guaranteeing that products remain safe and intact, regardless of the external conditions they face. Learn how the Gelbo Flex Test can enhance your packaging quality and ensure long-lasting reliability.

Gelbo Flex Durability Tester Compliance with ASTM F392

“The Gelbo Flex Durability Tester is an essential instrument used to evaluate the flex resistance and integrity of flexible films, laminates, and barrier materials. Compliance

Crumple Flex Tester – ASTM F392 Film Gelbo Flex Test

“For packaging, ensuring that materials can withstand wear, tear, and flexing is essential for protecting products throughout their lifecycle. One critical tool used to test

Understanding Flex Cracking Resistance: Key Insights for Packaging Solutions

“Discover the importance of flex cracking resistance in packaging materials, its causes, and how to prevent it. Learn how flex cracking impacts your product’s integrity.”

什麼是抗撓曲裂紋性?

“Understanding ASTM F392 Standards and Gelbo Flex Tester Price for Flex Resistance Testing” Flex crack resistance is a critical property in materials, especially those subjected