“For packaging, ensuring that materials can withstand wear, tear, and flexing is essential for protecting products throughout their lifecycle. One critical tool used to test this property is the crumple flex tester.”

What is a Crumple Flex Tester?

A crumple flex tester is an instrument used to simulate the flexing and crumpling conditions a packaging material might encounter during handling, transport, and storage. The device typically applies a consistent force to a sample, simulating repeated folding or bending. This process helps manufacturers understand how the material behaves under stress, such as its resistance to cracking, creasing, or tearing when folded.

For packaging films, such testing is crucial to assess the material’s ability to withstand mechanical handling without compromising the integrity of the package or the product inside.

Main Parameter

| Flex Frequency | 45 /minute |

| ተጣጣፊ አንግል | 440° (90 mm) or 400° (80 mm) |

| Capacity | 3.5 N.m |

| Horizontal Stroke | 155 mm or 80 mm |

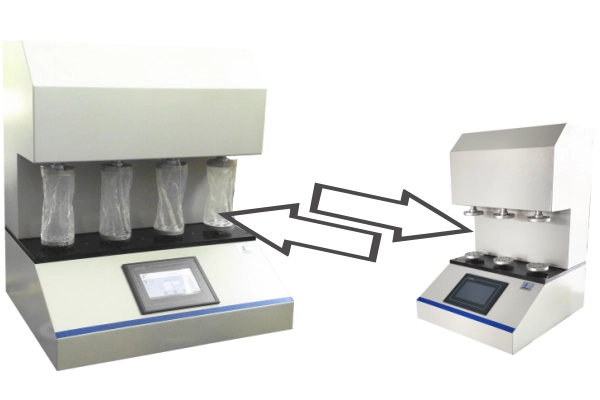

| Stations | 3/4 |

| Sample Size | 280 mm x 200 mm |

| Power | 110~220V |

Why is Gelbo Flex Conditioning Important?

When it comes to packaging, especially for food, medical devices, or sensitive products, the packaging must maintain its structural integrity throughout its use and handling. Crumpling or bending can lead to damage, affecting product quality and safety. By using a crumple flex tester, manufacturers can simulate these conditions and make data-driven decisions about material selection and packaging design.

How Does a Crumple Flex Tester Work?

A crumple flex tester works by applying a repeated, controlled bending action to a material. The test is usually conducted by placing the sample between two moving surfaces, where one side is repeatedly bent or flexed. The number of cycles the material can endure before showing signs of failure—such as cracking, tearing, or permanent deformation—provides key data about its durability.

The device often features an adjustable load and speed to simulate different real-world conditions. By altering these parameters, manufacturers can assess the material’s performance across various handling scenarios.

Crumple Flex Tester and ASTM F392 Standards

የ ASTM F392 standard provides guidelines for the testing of flexible materials to evaluate their ability to withstand crumpling and flexing. This standard is particularly useful in industries where packaging materials, such as films and flexible papers, need to be tested for durability.

Flexing action consists of a twisting and crushing motion following conditions A to D.

- ሁነታ ኤሙሉ ተጣጣፊ ለ 1 ሰዓት (2,700 ዑደቶች)

- ሁነታ ለሙሉ ተጣጣፊ ለ 20 ደቂቃዎች (900 ዑደቶች)

- ሁነታ ሐሙሉ ተጣጣፊ ለ 6 ደቂቃዎች (270 ዑደቶች)

- ሁነታ ዲለ 20 ዑደቶች ሙሉ ተጣጣፊ

- ሁነታ ኢለ 20 ዑደቶች ከፊል ተጣጣፊ

Incorporating ASTM F392 in the testing process helps ensure that the materials used in packaging meet industry requirements, providing consistent results in terms of material performance. The test procedure outlined in ASTM F392 ensures that the crumple flex tester produces repeatable and reliable data that manufacturers can trust.